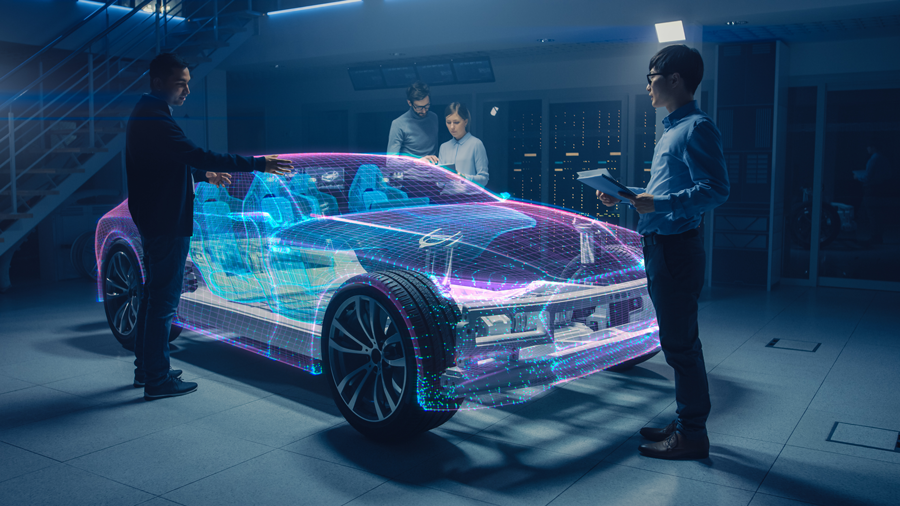

Collaborative Engineering Services: Automotive and Truck OEM and Supplier Sectors

For Current or New Products: Component and Assembly Product Design Optimization Concepts and Development, through Design and Validation, to Achieve:

- Labor Cost Reduction

- Material Cost Reduction

- Component and/or Assembly Weight Reduction

- Improve Capital Utilization and Achieve Capital Cost Reduction

- Component Part and Assembly Quality Enhancement via Application of Six Sigma and DMAIC Methods

- Application of Current Products to New Markets/New Customers

- Adaptation of Current Products to New Markets through Design Change

- Resolution of Manufacturing Problems and Issues

- Expansion of Organizational Capability in the Eyes of Existing or New Customers

Current and Future Manufacturing Process “Fresh Eyes” Reviews

-

Process Application and Selection for Appropriateness and Efficiency

Current Process Review for:-

Waste Elimination

-

Reduced Material Handling

-

Manufacturing Cost Reduction

-

Throughput Enhancement

-

Enhanced Manufacturing Capacity

-

-

Current Process and Plant Arrangement Review to Enhance Safety and/or Respond to Past Issues

-

Current and Future Process and Plant Arrangement to Reconcile Plant Footprint and Material Handling Requirements

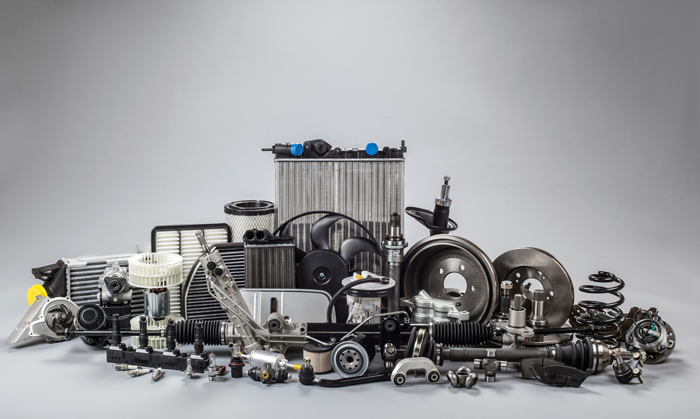

Primary Product Categories where Burnham Engineering Associates Possess Specific, Thorough Hands-On Experience in Vehicle Design and Development:

- Engineering Feasibility Support for Design Studio digital design and clay property development – Automotive, Medium and Heavy-Duty Truck

- Total vehicle packaging engineering, body and chassis, and vehicle systems integration for Internal Combustion Drive (ICE) Systems and Battery Electric Vehicles (BEV’s)-Automotive and Medium Duty Truck

- Automotive Body-In-White Optimization (design, stamping, welding, assembly processes, gage processing). General Motors, Ford, FCA.

Automotive Body mechanism designs to include door and window systems, seat adjustment mechanisms, closure mechanisms, and latching. - Plastic injection molding (component design, tooling, assembly, fixturing).

- Automotive and aircraft seating systems (metal frames and structures, foam, mechanisms, assembly processes, manufacturing plant launch).

- Automotive fuel systems (six-layer coextruded blow-molded tanks, fuel system modules, filler tubes (component design, tooling, manufacturing processes, assembly).

- Automotive roof racks and exterior body components (component design, tooling, manufacturing processes, assembly).